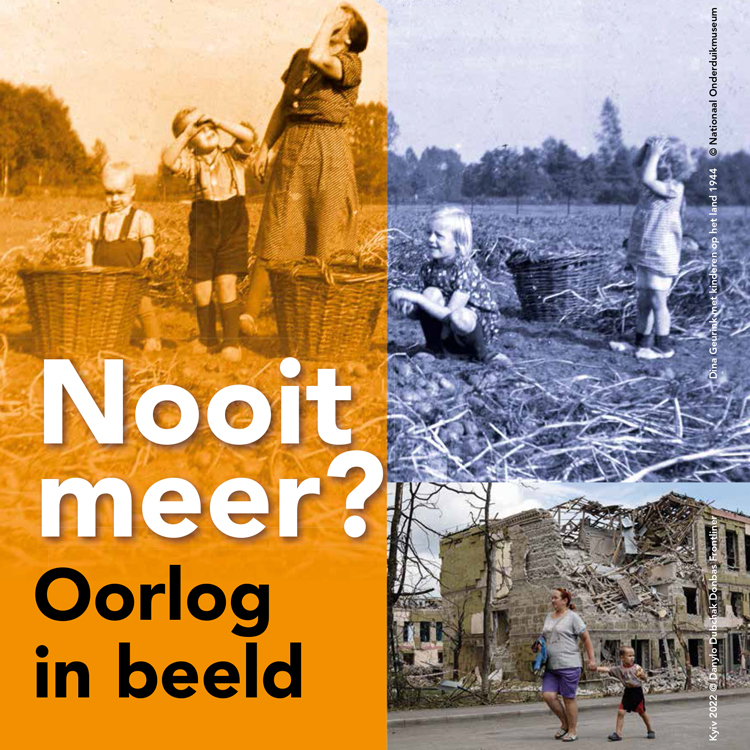

Met ‘kleine persoonlijke’ verhalen vertelt het Nationaal Onderduikmuseum over de grote geschiedenis van onderduiken en verzet tijdens de Tweede Wereldoorlog. Via de verhalen, keuzes en dilemma’s van gewone burgers in de grensstreek, ontstaat een beeld van een gemeenschap in gewone en ongewone tijden.

“Met kleine verhalen de grote geschiedenis vertellen, verbinden aan democratie en rechtstaat nu.’

Het huis werd tijdens de bezettingsjaren bewoond door de familie Kempink, een gezin met twee jonge kinderen. Op de zolder is nog de plek aanwezig waar acht onderduikers waren verstopt. Vanwege de centrale ligging in het dorp had de Duitse Ortskommandant zijn bureau gevestigd in de voorkamer van hetzelfde huis. De gewelfde kelder was tijdens bombardementen een schuilplek voor de hele buurt.

Ga op zoek naar de verhalen van mensen die de oorlog zelf hebben beleefd en verbind deze met de actualiteit. Ervaar hoe moeilijk het is om stroom op te wekken en hoe benauwd het in de onderduikruimte was. Leef in de opkamer mee met evacués uit Scheveningen die vanwege de Atlantikwall hun woonplaats moesten verlaten.

ervaringen

steun ons

Er zijn verschillende mogelijkheden om ons te steunen, bijvoorbeeld financieel door middel van een donatie of nalatenschap, (zakelijke) vriend worden of door vrijwilliger te worden. Kijk op onze pagina ‘Steun ons’ voor de mogelijkheden.